When cutting hard materials such as natural stone, masonry and concrete, knowing which blade to use can help you save work time and prevent material waste.

Diamond saw blade is actually a cutting&grinding tool. It works by the fact that when the saw blade is rotated, the exposed diamond on the surface of the diamond blade grinds the material being cut into a fine powder. The exposed diamond eventually cracks under pressure and heat and falls from above, exposing more diamond as the bonded part of the diamond wears away, allowing the blade to maintain its effectiveness.

Once you have decided to use a diamond cutting blade, in order to work better, there are ways you need to know to choose the best saw blade. You need to understand the type of material you choose to cut, the equipment you use, the size of the saw blade, and whether it is a wet or dry cut.

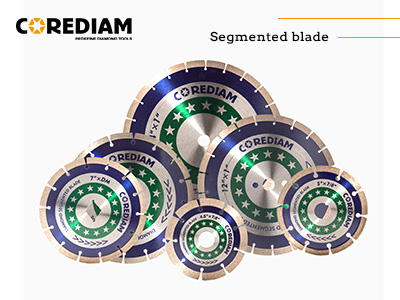

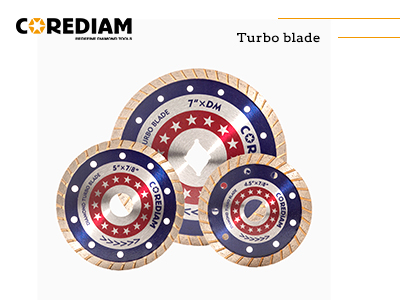

Here are the three most common types of diamond saw blade segment.

1. Segmented blades are the most popular universal blades. They typically have a medium to hard binding force that produces the coarsest cuts. The incisions between segments make these blades usable for dry cutting applications. Because the air flowing between sections helps cool the blade while cutting. Segmented blade are commonly used in concrete, abrasive materials and asphalt.

2. Turbo blade. The continuous turbo design achieves cleaner and faster cutting by forcing the material to be cut apart as the blade rotates, and the air flows between the cutting surface and the material to be cut, so that the temperature of the saw blade is not too high, which has the effect of cooling the saw blade. Holes scattered around the blade's steel core also help with cooling. The turbo saw blade can be used in both dry and wet environments. They have a soft to medium bond and can be used to cut tiles, natural stone, marble and granite.

3. Continuous rim blade, which is a saw blade through a softer binder, is most suitable for cutting hard materials and can easily cut ceramic tiles and ceramics. It cuts cleanest, making it ideal for cutting exposed surfaces of marble and granite. Since this type of saw blade has a continuous edge, water is needed to keep the blade cool during use, which helps to extend its service life.

Diamond saw blade is sometimes called soft, medium, hard, mainly because the use of different adhesives, adhesives are fixed by diamond particles to the matrix of a metal mixture, different adhesives have different wear rates, according to the market and test experience that softer cutting materials need to use harder saw blades, softer saw blades are often used to cut harder materials.

Our company can provide these three types of saw blades, segmented blade,continuous rim blade, turbo blade, for cutting different materials, have any diamond tool needs, you can see our product page to choose!

Message Board-