1. First of all, ceramic tile is a hard and fragile material. During the cutting process, due to mutual friction, it will generate a lot of heat, which is especially easy to break the tile, so a special saw blade is required for cutting. The best choice for cutting tiles is a diamond saw blade. Diamond saw blades work well when cutting tile.

2. The following are several recommended diamond saw blades suitable for tile cutting:

The first is a cutting disc for ceramic with a silent groove, which can reduce the noise generated during the cutting process. It is produced by sinter hot-pressed technology. It has higher performance, longer cutting life and higher cutting efficiency. The edges are sharp. https://www.corediamtools.com/tile-cutting-blade/sinter-hot-pressed-continuous-tile-cutting-blade.html

The second type is the continuous tile cutting saw blade, which provides a very fast, precise, smooth cut with minimal chipping, making it ideal for cutting hard materials without easily damaging the surface of the cut material. https://www.corediamtools.com/tile-cutting-blade/high-quality-diamond-tile-blade-with-silent-slot.html

The third type is the ultra-thin diamond K Turbo blade, the K Turbo segmented design adds cooling and dust extraction for fast cutting speeds with minimal chipping and soft, fine cutting edges.![]()

The fourth type is super thin diamond mesh turbo blades, designed for fast cutting and stable life in ceramic tiles, tiles, marble, granite, slate and similar materials.

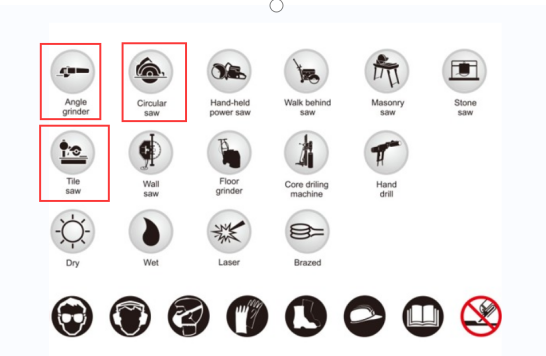

3.Cutting Equipment

After choosing the right tile diamond blade, you also need to choose the right equipment to use. Examples are angle grinders, circular saws, tile saws, etc. Using a saw blade to cut tiles is a very delicate job, we must choose the correct equipment to use it, the above three equipment can do the job very well. However, it should be noted that the hand grinder needs to be used by the worker. There are certain requirements for the operation of the worker, and a certain understanding of the equipment is required to avoid damage to the tiles during the cutting process. After all, a little shaking during cutting may cause the tiles to be cut. The surface is incomplete.

4.Cutting Environment

wet cutting

Wet cutting uses water to cool the saw blade during the cutting process, reducing the high temperature generated by the friction between the saw blade and the cutting material during cutting, which can make the equipment work for a long time, improve work efficiency, and prolong the service life of the saw blade. Avoid the distribution of debris and dust during cutting to ensure safety.

5.Summarize

In short, before choosing a diamond cutting blade, be sure to clarify the type of cutting material, such as its hardness, etc. At the same time, you also need to consider the equipment used, choose the appropriate cutting equipment according to the selected saw blade, and clarify what kind of cutting The environment can use saw blades. If you have any questions, please feel free to consult and contact us.

Message Board-